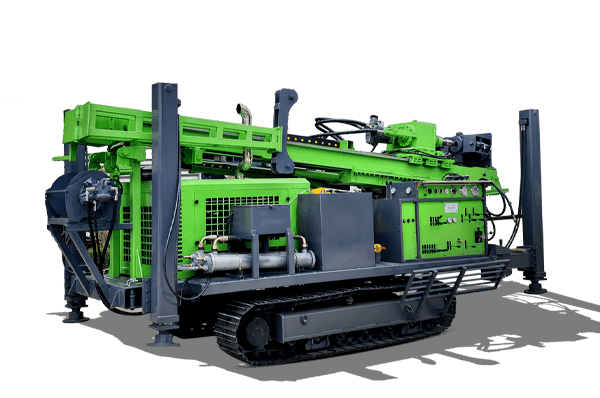

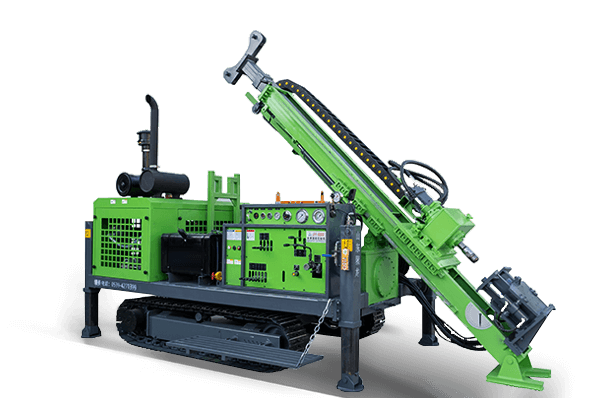

Key Points of Drill Rig Winter Maintenance

In low temperatures during winter, the maintenance of drill rigs is crucial for their operation, efficiency and safety. The key aspects lie in hydraulic oil, antifreeze, engine warming-up and brake fluid.

- Hydraulic Oil: Select the one suitable for low temperatures. When changing the oil, drain the old oil completely, clean the system and pay attention to the oil level to prevent low temperatures from affecting its fluidity and the system's efficiency.

- Antifreeze: It prevents the cooling system from freezing, resists corrosion and raises the boiling point. Check the level and freezing point. Add if insufficient. Replace it every two years or as recommended. Clean the system before replacement.

- Engine Warming-up: Before starting, turn on the power for pre-lubrication first, then let the engine idle for 5 - 10 minutes. Observe the instrument panel to ensure everything is normal, guaranteeing a good working condition of the engine.

- Brake Fluid: Low temperatures affect braking performance. Check the level and quality. Add if low. Replace if it's not good. Follow the regulations when replacing to expel air and ensure sensitive and reliable braking.

Proper maintenance in these aspects can ensure the stable operation of the drill rig in winter, reduce failures, extend its service life, improve efficiency and ensure safety.